Agriculture Solution

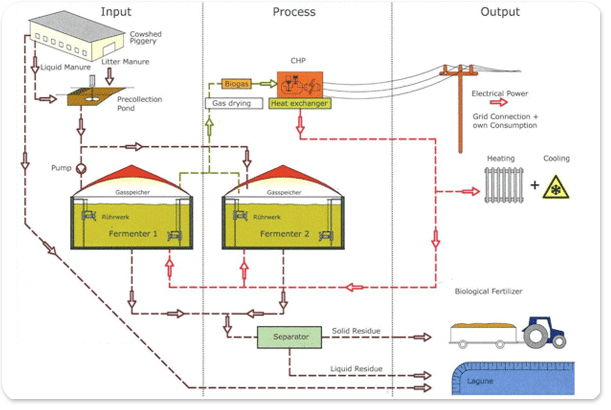

We provide standard digester systems for agricultural organic waste including animal manure, silage from plants and slaughterhouse leftovers. Our digester system, especially for manure, is based on a one-step process. Manure is collected in a nearby sump and then fed into the digester. The fermentation temperature is mesophilic (about 40-42°C) with a retention time (depending on the substrate) of 20-40 days to maximize gas yield at low investment costs. This biogas is fed into a CHP to produce electricity and heat/cooling energy, or upgraded to bio-methane to use as car fuel. The residue of the digester is not redundant and can be separated or used directly as an effective fertilizer. Biogas improves the food quality by replacing chemical fertilizer with organic minerals to the cropland for sustainable agriculture, improving people's health.

The main advantages of our systems are as follows: low investment costs, low operating costs and a high level of reliability.

- Our digester system is flexible for input sources varying from 6% to 30% dry matter and provides effective and specific sand cleaning technology to solve problems caused by sandy dung.

- The digester is a gas-tight, completely sealed tank made from steel or concrete with two foil layers and a bio-desulphurisation system inside. This provides savings in terms of external equipment costs.

- The low-maintenance and energy saving flexible submersible motor agitator system ensures the complete blending of substratum within the fermentation process to avoid problems from layer scrum, foaming and contraries like sand.

- The automated operation system ensures ease of use and operational convenience even if operational know-how is lacking.

- System maintenance can usually be carried out while the system is running, providing efficient hourly use and maximizing operating hours.